Biodegradable plastics are innovative materials developed for specific applications to enable a circular use of resources. In these applications, biodegradability in the intended end-of-life can help for example, to reduce the formation and release of persistent microplastics into the environment. For instance, certified compostable biowaste bags are designed to biodegrade under industrial composting conditions and help diverting biowaste from incineration and landfilling to produce compost as organic fertilizer for agricultural soils. Certified soil-biodegradable mulch films provide the same agricultural advantages of conventional films. However, non-biodegradable mulch films are difficult to be completely recollected and often are so heavily contaminated that recycling is no longer possible or economically sustainable. Certified soil-biodegradable mulch films at the end of the application phase can be ploughed into soil where the material is completely biodegraded by soil microorganisms, leaving no persistent residues. Thus, certified soil-biodegradable mulch films can be a sustainable alternative to replace conventional mulch films.

To ensure the biodegradability of the plastic products under the intended end-of-life scenario, certification schemes have been developed. This certification can only be achieved if the plastic material fulfills numerous criteria which are assessed in laboratory experiments and, in some cases, also in field tests according to internationally standardized methods. In laboratory tests for example, the biodegradable plastic must achieve an acceptable percentage of biodegradation within a defined time when it is exposed to an environmental sample from a specific habitat. For example, a material to be used to produce certified soil-biodegradable mulch films must be biodegraded in a standardized laboratory soil biodegradation test to 90% in 2 years to comply with the standard EN 17033. The 90 % threshold considers that during the biodegradation process a fraction of the carbon from the material is incorporated into biomass (in this case 10 %), as for any other natural biodegradation process. Importantly, certified biodegradable plastics are designed to be used in specific applications and be degraded after their use phase in an intended of end-of-life scenario. Certified compostable fruit and vegetable bags, for instance, are designed to degrade in industrial or home composting conditions. It is therefore misleading to expect that these products are a solution to littering and therefore their uncontrolled disposal into the environment should be avoided as for any other material.

What are biodegradable plastics made of?

Certified biodegradable plastics are blends made from bio-based1 or synthetic polymers, such as polybutylene adipate-co-terephthalate (PBAT), polybutylene sebacate-co-terephthalate (PBSeT) and polylactic acid (PLA), and polyhydroxyalkanoates (PHAs), as well as additives of no concern, regulated by certification schemes. Like natural polymers such as cellulose or starch, biodegradable polymers chemically differ from non-biodegradable polymers because they contain structural features that can be seen as “breaking points”, which allow the degradation of the polymer by microbes.

How does the biodegradation process work and what affects biodegradability?

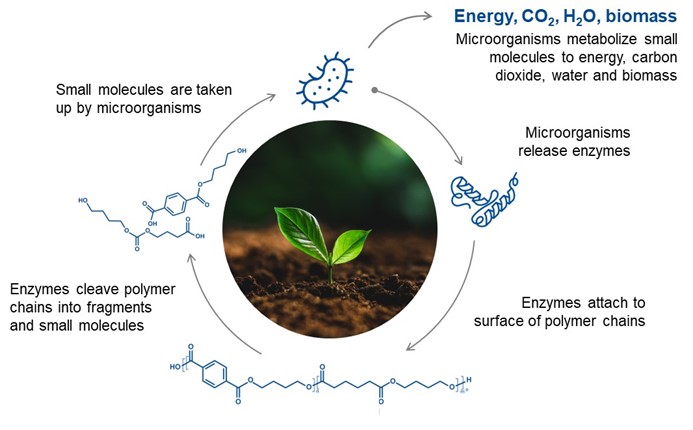

The breakdown of the (bio)polymer is performed by microorganisms such as bacteria and fungi which naturally occur in a specific environmental compartment. These microorganisms release enzymes into the environment which degrade the plastic material sequentially into fragments and subsequently small molecules. The small molecules are taken up by the microorganisms as a source of food and energy to survive and grow. Consequently, the carbon from the polymer is converted into carbon dioxide and biomass (e.g., cell membrane material). The biodegradability of a plastic depends not only on material properties such as chemical structure and crystallinity or on the microbes present in the habitat, but also from other habitat specific factors, such as temperature, humidity, pH and UV radiation.